Hardface Pipe System – Optimized performance, service life and profitability

Hardface pipe systems are used in processes where transportation of fly ash, waste, meat and bone meal, cement, coal, glass particles and corrosive and aggressive vapors expose equipment to excessive abrasion. Hardface pipe systems provide lower weight, better performance and longer service life, which contributes to significantly improved profitability.

Customized abrasion protection

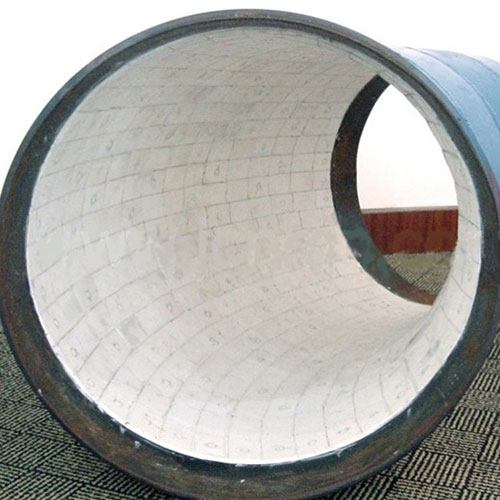

Hardface Pipe systems are made of steel pipes with an inside coating of a ceramic or chromium carbide. Examples of ceramics used are alumina, silicon carbide, chromium carbide, zirconium oxide and tungsten carbide. They provide significantly better performance than other hard materials such as densite, hardened steel and basalt. Manufacturing is made according to the customer’s needs with an abrasion protection that is adapted to the materials, flows and temperatures to which the pipe system will be exposed. Hardface can deliver tubes in sizes down to an inside diameter of 40 mm.

Efficient flow and multiply life

With a ceramic abrasion protection, smooth inside and pipe bends with perfect even radius, Hardface Pipe System ensures a more efficient flow while avoiding harmful turbulence inside the pipes. With Hardface solutions, the life of the pipes doubles compared with alternative solutions, which contributes to better profitability due to longer maintenance cycles and reduced risk of unforeseen production shutdowns.

Pipes with ceramics

Hardface has expert knowledge in ceramic applications and can offer different types of ceramics to solve mechanical abrasion problems.

Alumina

Chemically very stable material with high resistance to wear with a hardness of about 9 on the Mohs scale. Density 4 g / cm3.

Zirconium oxide

Similar to alumina but has greater resistance to mechanical wear and tear. Density 5.7 g / cm3

Silicon carbide

Has extremely high resistance to mechanical wear and high temperatures. Density 3.2 g / cm3

Chromium carbide pipe system

The inside of the tube is protected with a welded chromium carbide overlay. A tube protected with a chromium carbide overlay weighs less than a ceramic tube and has very high strength against abrasion and tolerates impacts better than ceramic materials. The hardness of different chromium carbide grades is as standard in the range of 50-64 HRC.

Do you want to know more?

For contact and more information, send an e-mail to info@hardface.se or call +46 70 781 70 00.

About Hardface

Hardface works to improve efficiency and competitiveness within the Swedish industry. We do this by offering durable solutions in mechanical wear for longer service life, more efficient maintenance work and better profitability. With a wide range of durable materials, consulting services and training courses, we offer customized abrasion resistant solutions to the Swedish industry where high demands are placed on the durability of the production equipment.