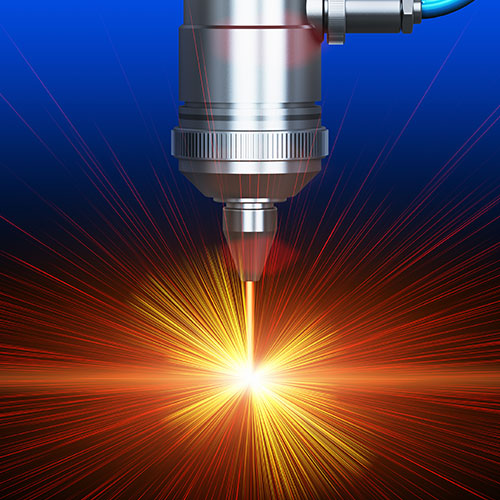

Laser Cladding

Maximum wear resistance and adhesion

Laser Cladding is a welding process that complements thermal spraying. It has become more used than PTA welding and it exceeds conventional welding methods such as TIG (Tungsten Inert Gas) for advanced welding repairs.

With Laser Cladding, the laser beam is focused on the workpiece with a selected point size. The powder coating material is sprayed with an inert gas through a powder nozzle into the melt. The laser optics and powder nozzle are moved over the workpiece surface to coat traces of selected material, such as tungsten carbide. The result is complete and even layers of large volumes.

Benefits

- Perfect metallurgical bonding to the base material

- Completely dense surface layer

- Minimal heating zone that minimizes deformations of the material

- A homogeneous microstructure for maximum abrasion resistance

- Sharp corners can be coated

Do you want to know more?

For contact and more information, send an e-mail to info@hardface.se or call +46 70 781 70 00.

About Hardface

Hardface works to improve efficiency and competitiveness within the Swedish industry. We do this by offering durable solutions in mechanical wear for longer service life, more efficient maintenance work and better profitability. With a wide range of durable materials, consulting services and training courses, we offer customized abrasion resistant solutions to the Swedish industry where high demands are placed on the durability of the production equipment.