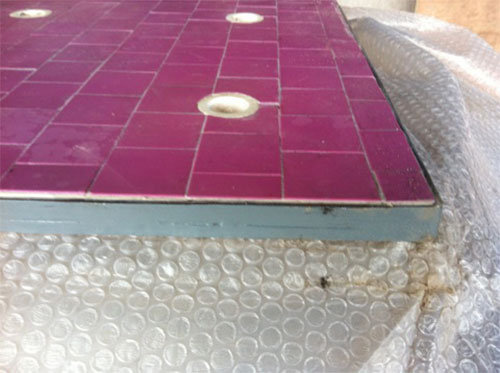

Ceramic wear plates for aggressive abrasion

Hardface ceramic wear plate is used in truly aggressive environments where heavy flows of rough materials causes impact and strain on the equipment. Hardface ceramic wear plate contributes to better abrasion resistance, higher payload and much longer service life.

Wear plates for demanding environments

Hardface ceramic wear plate has a very high resistance to mechanical abrasion and erosion. They are used with advantage as construction materials in truck dump bodies and barges that load and unload excavated gravel and rocks, for heavy steel scrap handling and at demolition work where concrete with iron reinforcement bars is released on the flat bed.

Lower noise level

The ceramics of the plates are mounted in a steel frame or vulcanized in rubber, which increases the resistance to impact and reduces the noise level due to rubber’s shock absorbing properties. They can be bolted or glued directly to the surface of the wear plate.

Manufacturing according to specification

Hardface always delivers an optimized solution where our ceramic plates are manufactured according to customer specifications. Taking into account, among other things, application and material flow, type of ceramic, dimensions and thickness, with or without rubber insertion, etc.

Do you want to know more?

For contact and more information, send an e-mail to info@hardface.se or call +46 70 781 70 00.

About Hardface

Hardface works to improve efficiency and competitiveness within the Swedish industry. We do this by offering durable solutions in mechanical wear for longer service life, more efficient maintenance work and better profitability. With a wide range of durable materials, consulting services and training courses, we offer customized abrasion resistant solutions to the Swedish industry where high demands are placed on the durability of the production equipment.