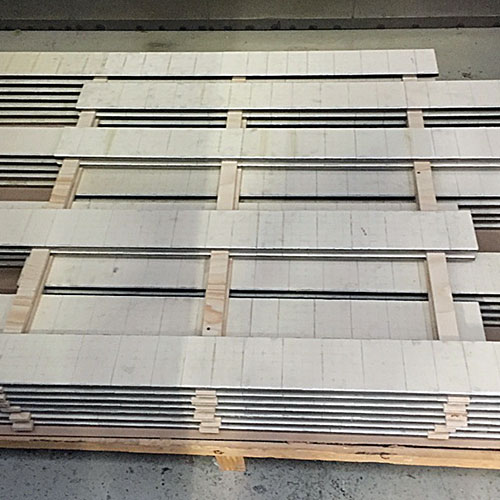

Wear bars for chain conveyors

Hardface delivers wear bars and sliding bars to all kinds of scrape and chain conveyors. Our solutions protect the conveyors’ treads, as well as scrapers and chains. Lower friction means less wear, lower noise levels and energy consumption, thus contributing to increased profitability through better performance, longer service life, substantially reduced maintenance costs and reduced risk of unforeseen production shut-down.

Heavy material flows with high abrasion level

Scrape and chain conveyors are often used in environments that exposes them to severe abrasion and erosion. Large and heavy material flows cause enormous abrasion on the equipment. Typical examples are handling of forest raw materials; timber, wood chips, pellets and ashes, where the chains run through dirt and gravel.

The type of application determines the choice of abrasion protection

Hardface manufactures the wear bars of construction steel and offers several different grades and qualities in stainless steel and Hardox. Depending on the application area, ceramics or chromium carbide are used as abrasion resistant layers on the plate.

Ceramic wear bars

Hardface has expert knowledge in ceramic applications and can offer different types of ceramics to solve mechanical abrasion problems. The advantage of ceramic is that the wear bars can be adjusted more precisely to the environment in which they are to be used. Ceramics reduce wear on the chain and provide a lower noise level for the conveyor.

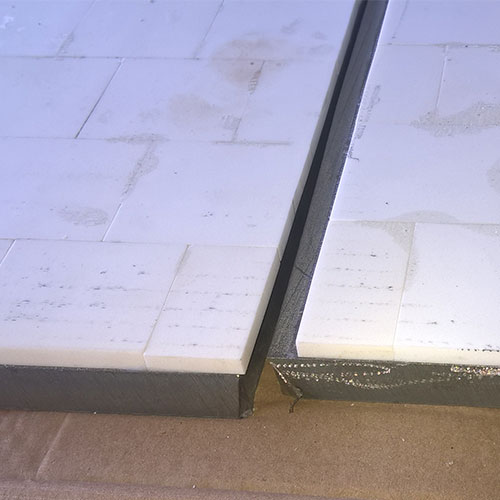

Alumina is the most common ceramic used for Hardface wear bars. It’s a chemically very stable material with high resistance to abrasion and hardness of about 9 on Moh’s scale. The ceramic is glued to the plate by vacuum technology, which provides superior adhesion, impact strength, abrasion protection and durability.

Chromium carbide reinforced wear bars

Hardface chromium carbide plate provides a cost-effective wear protection for scrapers and chain conveyors. It is also a well proven material for wear bars providing them with multiplied resistance to impact and abrasion compared with ordinary steel grades. Hardface chromium carbide wear bars are ready to be mounted as soon as they are delivered.

Hardface wear bars

Hardface delivers wear bars that are fully adapted to our customers’ needs. The wear bars are manufactured in the material that best suits the conditions of the production process.

Hardface wear bars contribute to:

- Increased abrasion resistance, impact resistance and life-span

- Minimized friction

- Lower noise level

- Reduced abrasion on scrapers and chains

- Lower maintenance costs

Do you want to know more?

For contact and more information, send an e-mail to info@hardface.se or call +46 70 781 70 00.

About Hardface

Hardface works to improve efficiency and competitiveness within the Swedish industry. We do this by offering durable solutions in mechanical wear for longer service life, more efficient maintenance work and better profitability. With a wide range of durable materials, consulting services and training courses, we offer customized abrasion resistant solutions to the Swedish industry where high demands are placed on the durability of the production equipment.